Tire Set-Up

In the beginning, people run Mini-Z with the tires on the wheel holding on by friction. Latter on, rim tape was used to keep the tires from coming off especially soft rubber tires. Then racers found the outer edge of the tire tend to tuck under during high speed cornering. This cause the rear of the car to skip, and in some case flip over. Racers started to super glue the tires to the rim. Delrin rims were used since it is resistance to solvant used to remove the glue. The latest trend is to shave the tire down from the stock rubber from 2.5mm thick down to 1-1.5mm thick. Shaving the tire in Mini-Z is done for different reason than shaving tread on full scale race cars. Full scale race car shave the tread to minimize the heat transfer path to cool the rubber, and prevent melting. Mini-Z don't have melting rubber issue that anyone know of yet, but shaving the rubber lower the aspect ratio, and result in less tire flex. This gives sharper handling just like how a lower aspect ratio tire in real race car improves performance. The tire will have to be glued to the rim before cutting. Usually, the Hudy Micro Tire Truer along with an adapter is used to trim the tire. Tire cutting is very useful in high traction track where tire flex becomes an issue. For lower traction tracks like carpet, it may not be as useful to cut the tire. An added benefit of cutting tire is with more consistent handling, the car is less likely to suddenly loose, then regain traction again, which results in flipping.

Althought Mini-Z tires do not heat up to melting point like in full size cars, but they do heat up. As the race progress, tires increase in traction as tire warms up. With soft tires like PN 6 degree rear tires, you will get excellent traction during the race, but after about 6 minutes or so, tires heat up to the point where they are too soft, and begin to loose traction again. It can result in an unexpected crash just at the end of the race when the rear tire give out.

Here is a story of what happened with tire overheat. At the 2009 KO Propo race, I was watching EJ Evans from T.O.P Racing drive his modified MR02 with prototype PN A-Arm suspension. He had the fastest qualifier, and was leading the race the entire time during the final. I was hoping he would score a win to showcase the advantage of the double A-Arm suspension. He was going around the first corner after straight at maximum speed with the rear tires scrubbing all the way around searching for traction. It was very impressive driving. He held the lead until near the end of the race. Several other drivers lost rear traction due to tire overheat from aggressive driving and crashed. I was hopping EJ's rear tires would hold out. A minute or so to go, the rear of his car started to squirm more than usual. In the next lap, the rear end gave out, and spun the car out. The next lap also resulted in a spun out. Luckily, EJ instinctively altered his driving, and compensated for the loss of traction. Believe he ended up in second. Still very good. Lesson learned is that tires can loose traction towards end of race when they heat up. Shaving the tire should help out. First, it will improve heat transfer to the rim. Second, lower aspect ration is less susceptible to tire flex. At the KO race, very few people shave their tires. EMU and Grant were the first racer I know to realize the benefit of shaving tires. Now many racers do it.

Tire Testing Machine

--->This section has old information, but still intersting information, so I won't delete it yet. Someday I will build a better tire test machine with latest tires shaved and unshaved.

Tires are the most important part of handling. Is the biggest performance improvement you can make. There are many tire choices and just as many opinions on which is the best. In general, most people have settled on 8 deg for rear and 15-30 deg for front. I decided to do some testing myself to try to get some numbers. Real tire test machines is way out of my means. I just wanted to use what is around the house. Is not a formal test, but is just to satisfy my curiosity. Word of warning. Conclusions drawn here are not the final authority. I like to trust them, but that is just my opinon, it actually contradicts what various expert drivers believes.

Tires come in different size and degrees. Normal width are used for front, and wide are for rear. Kyosho makes simi wide that can be used in the front, but testing so far shows there is no advantage to it. Tires come in only one diameter, 20mm ID and 25mm OD for both front and rear. Degree in tires is not about angles, but rather the hardness of the rubber. It is generally accepted that the lower the degree, the more traction and higher degree has less traction. In Kyosho nomenclature tires go from 20 deg to 60 deg. Most aftermarket tires use a different scale that goes from 8 deg to about 35 deg. 8 deg is about equivalent to 20 deg Kyosho tires. For the test, I will be using GPM tires bought from RCXmini.com. It is just because they are the lowest cost tires that allows me to buy multiple samples of different hardness, and I had good luck with them.

Questions I wanted to answer are:

1) Is rear motor faster or is mid motor faster. That answer depends on whether having more weight on the tire improves traction. More weight means more centrifigal forces, so the tire would have to hold on tighter to overcome the added weight. Question becomes whether coefficient of friction goes higher with more weight.

2) Do mini-z tires behave like a car tire with similar slip angle characteristics. Typical full scale car slip angle characteristic curves is shown here. This picture is linke to the http://www.donpalmer.co.uk performance driving web page.

3) What is the difference between different hardness.

By driving around the track and trying different tires and chassis, I have some seat of the pants answers. Mid motor car is faster than a rear motor. Mini-z tires seems to behave like a full size racing car tire in terms of slip angle characteristics. With the GPM tires, I don't find any better traction going from 8 deg to 25 deg tire. In fact, I feel traction actually goes up when you go to a 25 degree tire. 15 degree tires however is more slippery.

A simple tire testing machine was made out of some VEX Radio Shack robot parts I have laying around the house. We had a VEX robot competition at work, and they gave each team a VEX kit. Is worth about $250. We were suppose to give it back after the competition, but that never happened. The kit is chump change to a big company anyway.

Here is the tire

test robot with the remote controller.

Here is the tire

test robot with the remote controller.

Tire is mounted

to the end of the arm at an angle. A protractor is used to set the slip angle.

Tire is mounted

to the end of the arm at an angle. A protractor is used to set the slip angle.

The arm operates a

kitchen scale that measures side force down to 1 gram. Proper proportioning

is used to calculate force occuring at the tire.

The arm operates a

kitchen scale that measures side force down to 1 gram. Proper proportioning

is used to calculate force occuring at the tire.

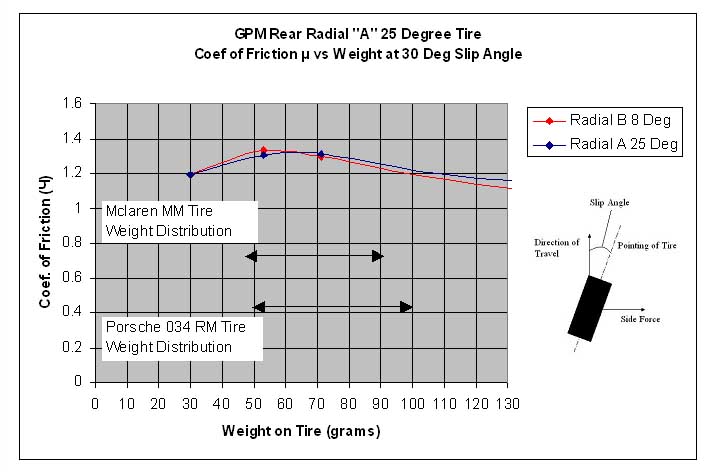

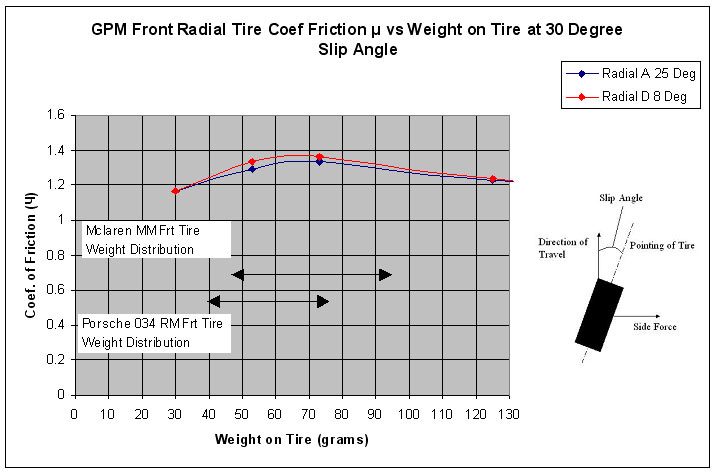

1) This graph answers the question on whether MM or RM is faster. For the McLaren, the weight distribution is 95gram/92gram front and back, or nearly 50%/50% distribution. For the Porsche 934 RM, the weight distribution is 78gram/100gram front/rear or 43%/56% distribution. As seen in the chart below, the wieght on the tire does not affect performance that much. In either case, RM or MM will have about the same side grip in the back.

Same test shows that for the front tire, the performance decrease when there is more weight on the tire. Therefore, a RM will have more front wheel traction than a MM in steady state cornering.

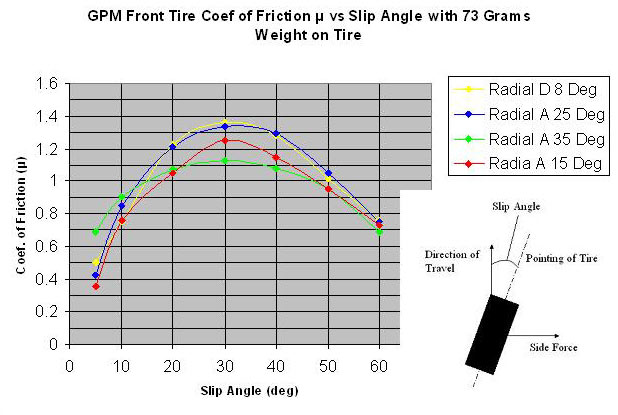

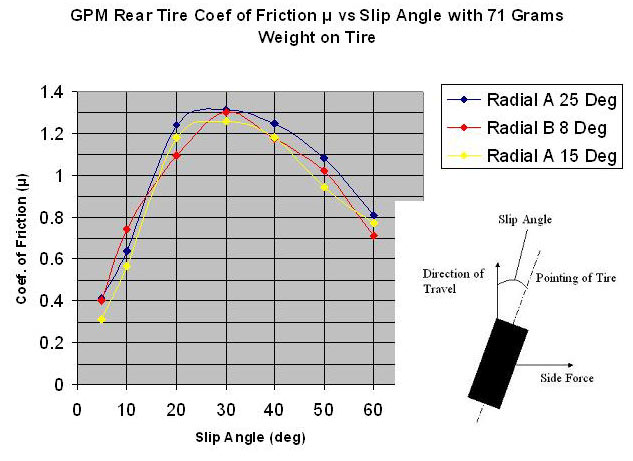

2) and 3) The graph of slip angle versus coef of friction is similar to one generated by full size cars. Most traction is generated at 30 degree slip angle. After that, traction drops. This graph is intersting in that it shows both 8 deg and 25 deg tires have the same traction. Therefore, both should not be any performance difference. That is backed up by my own experiance. However a 25 deg tires wears longer, and because it is stiffer, it tends to stay better on the wheel. That means in general, 25 deg tire should be used. At 35 deg, you start to loose traction.

For the rear tire, 8,15 and 25 degree tires have about the same traction. The 8 and 25 have slightly more traction than the 15 degree tire as in the front case. It is interesting to note that the rear tire eventhough it is wider, has about the same ultimate traction as the narrower front tire. Therefore, a narrow tire can be used on the back for the same performance.

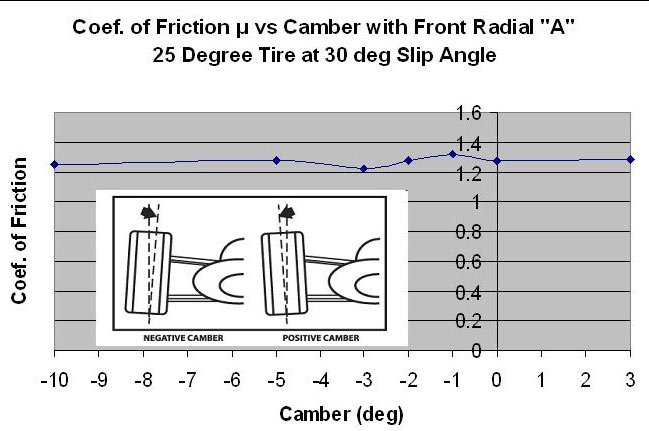

Since the width of the tire have no affect on traction, using the same reasoning then the camber of the wheel should have no affect on the traction either. Test indeed shows that camber of the wheel have no affect on traction. Conclusion, you should pick a camber that gives the most even tire wear.

Note that all these tests are measuring a constant slip on the tire. That means a dynamic friction rather than static friction is measured. With the equipment I have, is difficult to gage peak friction associated with static friction. I assume that higher dynamic friction equals higher static friction. From observing the scale, there is an initial jump in tire side force then it settles on a steady sliding force. That initial jump assuming it is the static friction is about 5-10% higher than the steady state slide side force. Although from reading other web sites about tires, I am not sure if tires are suppose to have static and dynamic coef of friction as in an object sliding. Tires are always flexing and slipping, so the classical static and dynamic friction probably does not really apply here. This is just a start of a tire test. I believe proper testing with good equipment that can measure peak force can yield important handling information about mini-z cars or any other R/C cars.