Design Corner

I like working on mechanisms. That is my day job. When there is some spare time, I help design some of the parts for PN Racing. That part is voluntary and for fun. If you want to see a neat new product come out, then the best thing to do is to design it yourself. Then you get to be the first to try it out when the prototype comes out. There are always ideas to make mini-z more interesting and perform better.94mm Rear Motor Mount

The 94mm chassis is quite competitive. It is shorter than 98mm, which is stable, and longer than 90mm, which is too twitchy. Is a pretty good compromise. The only problem with it is that all the motor mounts on the market has the motor pretty high up. Motor is not as high up as the high mount, but is between 98mm mount and high mount. For the new 94mm LCG mount, motor is lowered by 3.25mm. In mini-z handling, that is quite significant. The handling is immediately noticeable. Most drivers noticed the improvement in the car. It was interesting to note that at the 08 worldcup, a vast majority of the people running 94mm chassis use this LCG mount. Pretty sure all the podium racers used it.

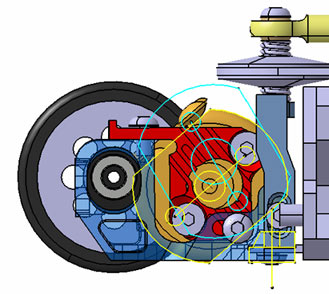

98mm Motor Mount

The 98mm rear motor mount is similar to the 94mm motor mount. The motor is even

lower than the 94mm mount.

MR020 Sway Bar

Sway bar is useful for stabilizing the front end of the car. This sway bar design allow for smooth suspension travel. Since PN came out with the sway bar, Atomic also has a version of the sway bar that is similar. However, the Atomic one does not work as well. The spring cup will angle up and down as the sway bar rotates up and down. That may cause some unwanted spring deflection.

90mm Motor Mount

See anything wrong with the picture above? The Toyota AE86 is on a 90mm chassis. Chassis shorter than 94mm are not competitive because they only come with rear motor or high motor mount. Neither of which are very fast. For a long time Atomic made a 90mm high mount for the 90mm chassis mainly for the hatch backs like Mini Cooper, Toyota Vitz or Honda Fit. They go in a separate race class. Back in January 09, the KO Propo Mini-Z race opened a new 90mm class for all chassis shorter than 90mm. Phil approached me about designing a mid motor mount for 90mm chassis. He thinks it could be done, but would be very tight. The intent was to use the prototype to enter the 90mm class at the KO Propo race. The prototype actually made it in time for the March race. I was able to locate 2 F40 white bodies at an online shop in Sweden. Those were the last two before they sold out. The F40 is a 90mm chassis, but has the widest rear width of any 90mm bodies. Also, it is a low body. Motor mount prototype arrived a week before the KO Propo race. Phil tried it with the AE86 body, but needed something wider in the rear. I gave him one of the F40 body. We tested it on the track, and the handling was phenomenal. It was about as fast as a 94mm chassis. Could have been even faster. At the KO race, there was almost no competition. Phil's F40 easily took TQ, and lapped the field by 4 laps in the final race. Ok, not quite 4 laps. Joe Chen from Reflex Racing said that is a pack of lies :) He was second, and 3 laps behind Phil. That is actually very fast considering he was driving a Mini Cooper. I had the other prototype and used a F355 body. The back part of the body was a little too low, which resulted in very small suspension travel. It felt just enough, but in actual running it made the car handle strange. I was sliding all over the track. Should have used the F40 body, but I did not have time to paint it. Since they are so hard to come by, I wanted to do a good job painting it before running it. I was told there were many request for the 90mm mount after the race.

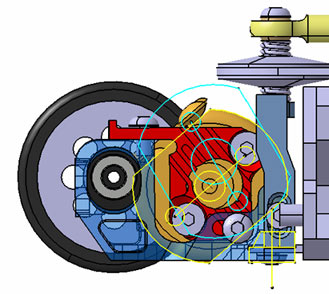

Unequal Length A-Arm Suspension

Unequal length A-Arm suspension is just facinating. Even as a kid back in grade school, I marveled at the usefullness of it. It allows for independent suspension travel, but kept the wheel vertical as the car rolled into corner. You always have maximum tire contact with the road no matter how the body rolled. Pretty much all full scale race cars use the uequal length A-arm. Mini-z have such realistic bodies, it would be the ultimate upgrade if you could add a realistic unequal A-arm suspension to it. After all, a realistic race car body has to have an equally realistic suspension. But before going too far, there has to be some product requirements:

-Must be the same width as current MR02 chassis. Bodies come with such realistic wheels, the A-arm suspension must be able to use the nice wheels that come with the body.

-Must be crash resistant. Unlike 1/10 scale, mini-z hit the wall or each other all the time. Even with the added linkage and complication, parts must not break or snap out in a crash. The suspension must be every bit as durable as the original MR02 suspension, and that is pretty durable.

-Ride height and suspension travel should remain unchanged.

-Suspension must fit on all existing bodies. There may be some exceptions like the Porsche 962 where the sloping front make make it impossible to fit. With some trimming, it should still fit.

With all these requirements that must be met for a good worthy suspension to replace the current MR02 one. The ball joint for the suspension is unlike anything out there. It is very durable. Grant crashed his car and rolled it many times. The suspension pieces never popped apart or yielded despite the extra linkages. For this design, it is impossible for the joint to come apart. All the parts are analyzed by computer finite element method to find the minimal weight and still meet strength requirement.

When the first prototype came, none of the parts fits. There were various mistakes. It took a while to figure out what was wrong and hand filed it to make it work. The first working suspension was at the 08 PN world cup in Las Vegas. An MR02 spring was installed, which is not the right stiffness. I drove it, and Phil drove it. The handling was hideous. However, there was a hint that it could be an excellent suspension. After some calculations to find the correct stiffness, I bent the right spring from an existing MR02 spring. Couple more set ups latter, it was running very good. Went over to Kennon and drove it there. It was apparent that the suspension worked brilliantly. Turn in was crisp, on throttle on steering was tight. Grant from Matsushimas Hobbies took one of the prototyped and spent many hours tuning it and testing it. He loved it. Said he would not go back to the stock sliding knuckle suspension. We had an eccentric cam on upper arm to test out different suspension positions. More testing and changes were done with help from Grant. The production suspension came with 5 optional spring as well as 2 different sway bars. Initial testing at Kennon by Phil showed the double A-arm suspension to clearly beat the stock sliding knuckle design by a wide margin. Phil was able to beat his best time on the track by couple tenths. He use to run 8.1, but with this, he ran 7.8. Not only that, but he was able to consistently turn in record time lap after lap. He got 7.8, 7.9,7.9,7.8 and so on. Usually, you only get the record time once or twice per run, and not lap after lap. The suspension is so consistent and offer so much grip that you could brake less in corners and get on the throttle sooner. It was quite exciting. For me, the realism of this suspension is the best thing, but good performance is of course good too.

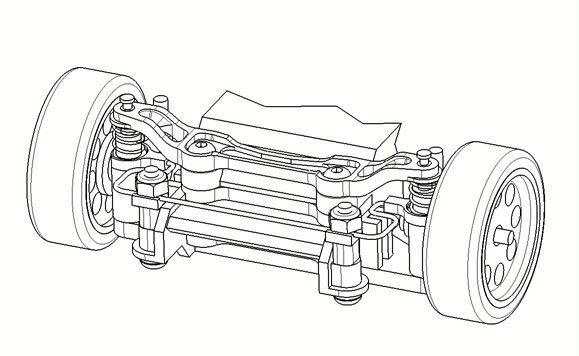

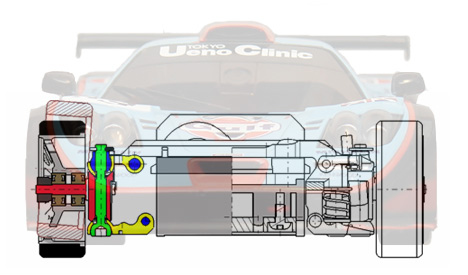

MA-010 AWD A-Arm Suspension

Kyosho showed the Lancia Delta MA010 at the RCX show in 05. That was the first time I saw a mini-z. It was a little expensive at $160. Would have bought it had it not been for the suspension. It was sliding knuckle on all 4 wheels. That is just one step away from having no suspension at all. The incorporation of an AWD mechanic into this scale is amazing. The suspension is a little of a let down. Atomic made a double a-arm for the rear end of the MA010 with mixed reviews. The plastic arms were too soft, and settings kept changing on the car each time it hit the wall. Latter aluminum version was better. However, no one has ever made a double a-arm for the front of the AWD car. It is thought to be impossible to fit all that into such a small space.

After the MR02 A-arm, work on the AWD A-arm started not long after the 09 KO Propo mini-z race. The requirements were similar to the MR02 a-arm.

-Must be the same width as current MA01 chassis. Bodies come with such realistic wheels, the A-arm suspension must be able to use the nice wheels that come with the body. Wider A-arms will also require longer driveshafts, which increase the cost of the suspension system.

-Must be crash resistant. Unlike 1/10 scale, mini-z hit the wall or each other all the time. Even with the added linkage and complication, parts must not break or snap out in a crash. The suspension must be every bit as durable as the original MR02 suspension, and that is pretty durable.

-Ride height and suspension travel should remain unchanged.

-Suspension must fit on all existing bodies that current MA010 chassis fit.

Prototype for the AWD A-arm came in October. Amazingly, all the parts fits the first time it was assembled. There were no interference or fitting issues. Front wheels were able to turn, and stay clear of all the drive mechanism. There was even clearance even for the Enzo body that normally in a MA010 requires holes for the knuckle posts. The front end handled very well. There were tons of steering per David G. However, the rear end needed some work to make handling acceptable.

My impression of driving the car was that it was very smooth and predictable. You can aim the car an inch or two from the wall on a sweeping turn, and it will hold the line thru any bumps on the track. It was so consistent I find myself driving closer and closer to the apex of the turn with no risk of hitting the curb turn after turns. There were a lot of steering, but still does not flip the car. The normal chatter that you get thru the corners were gone. There is just a hint of chatter. This is without using any grease on the shocks.

As a bonus, this suspension is very easy to adjust. Is not necessary to remove the cover plate to do any adjustments. Changing springs, droop, preload, bottoming and diff adjustment were quick to make with just one or two screws per wheel. Production units for the front is expected towards end of 09. Rear A-arm will have to wait another 6 months or so to work out some bugs.

MR03 Parts

The first part to make for MR03 is springs front and back. Other parts are in work.